¶ Voron Stealthburner 2 Piece Toolhead PCB

This guide steps you through the wiring and installations for Linneo's 2 Piece Toolhead PCB from hartk.

For the 1 piece Toolhead PCB, use this link.

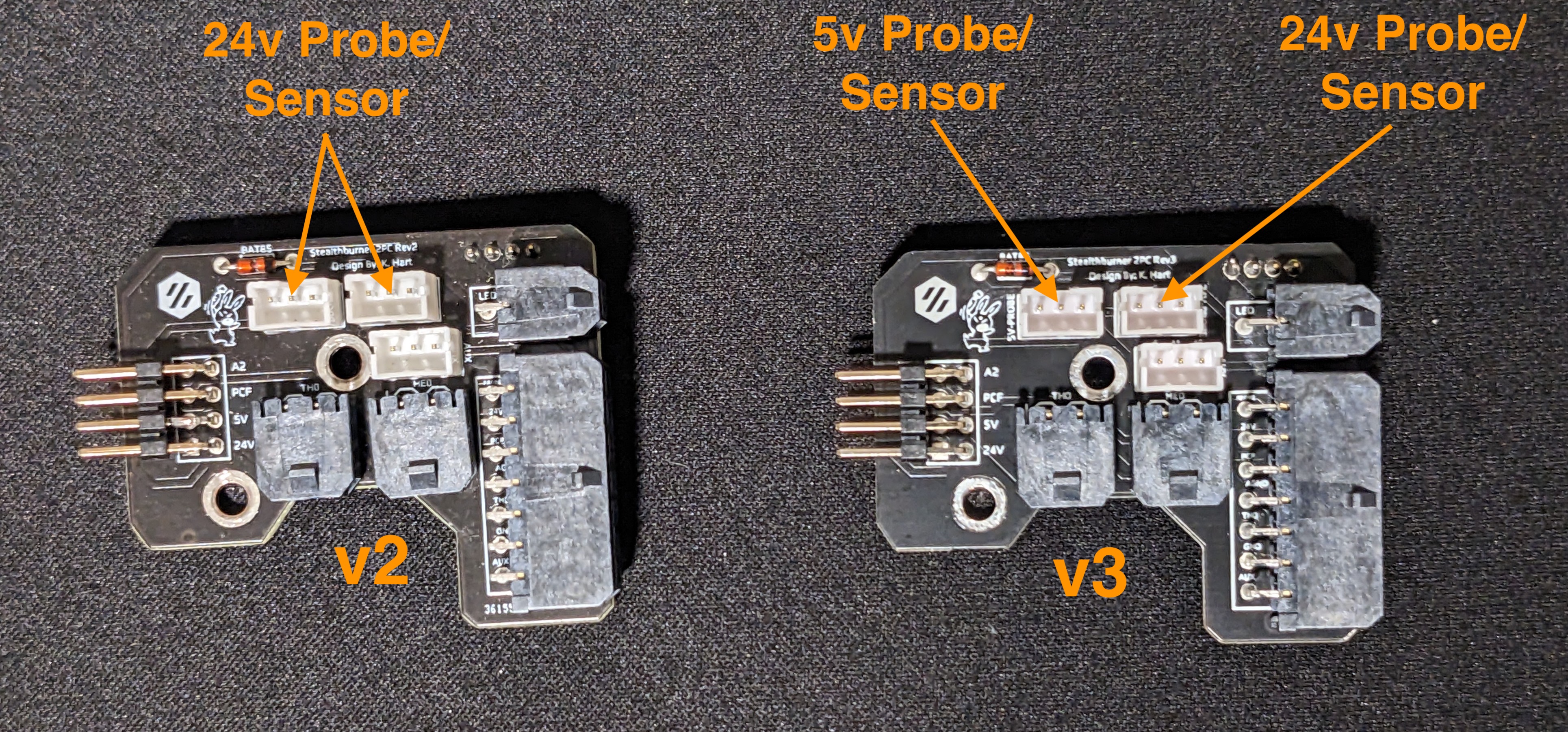

NOTE: This page covers both the v2 and v3 versions of the 2 Piece Toolhead PCB. We will flag differences where they apply.

To wire the 2 piece Stealthburner Toolhead PCB, you will need the following connectors…

MCU Connections

2-pin Vertical Molex Microfit 3.0

HotEnd/Thermistor

Probe/Stepper

The Probe and Stepper use JST-PH connectors, which are smaller than a normal JST-XH. Our JST-PH mini kit has all parts needed.

1x 2-pin

1x 4-pin

Fans/LED's

The Fans and LED's can use Dupont connectors.

2x 2-pin

1x 3-pin

You will also need the PCB Spacer, two M3x8 SHCS, two M3x6 BHCS and to ensure you put the appropriate heatsets in your SB toolhead, as per Page 13 of the Stealthburner Manual.

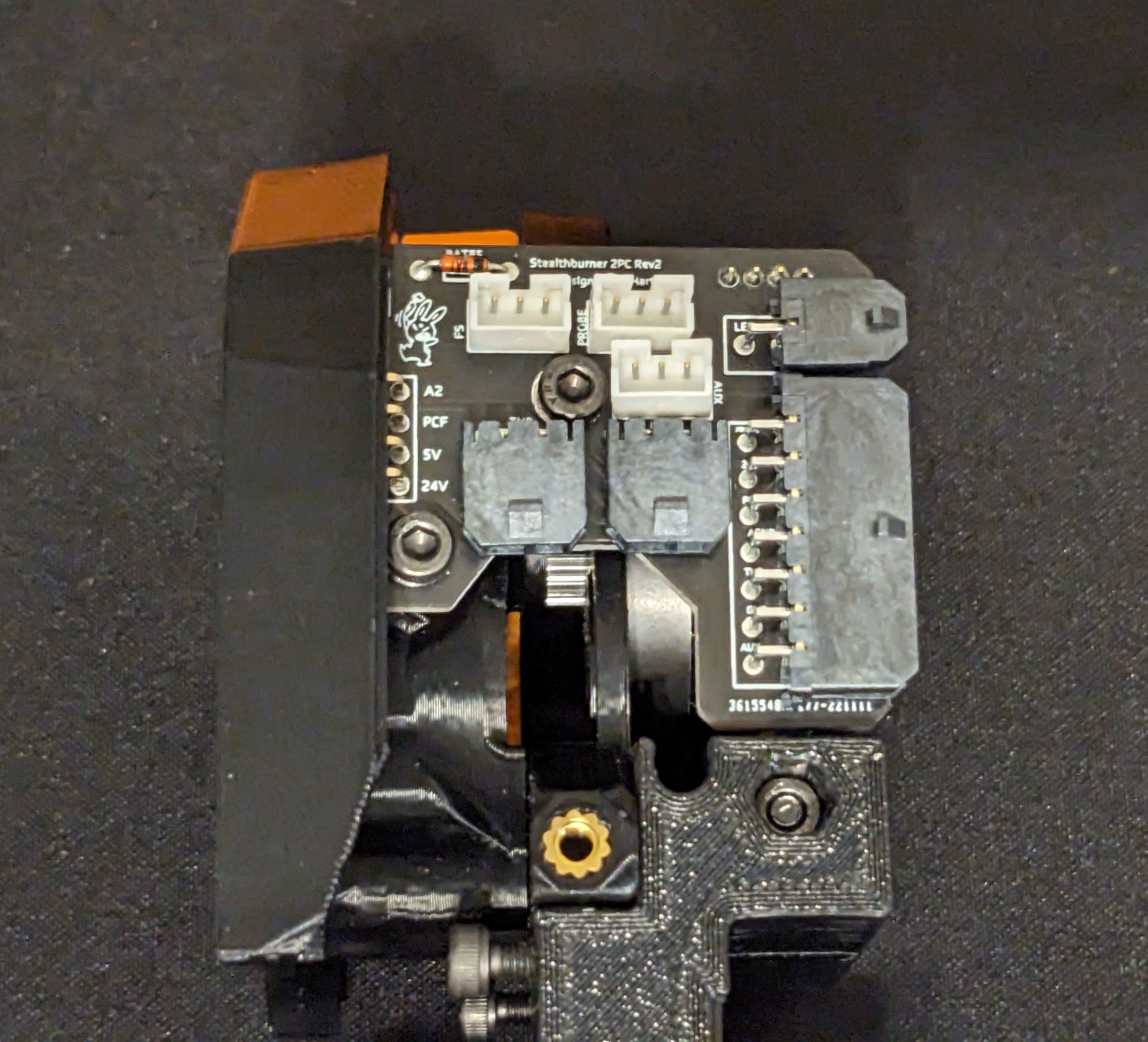

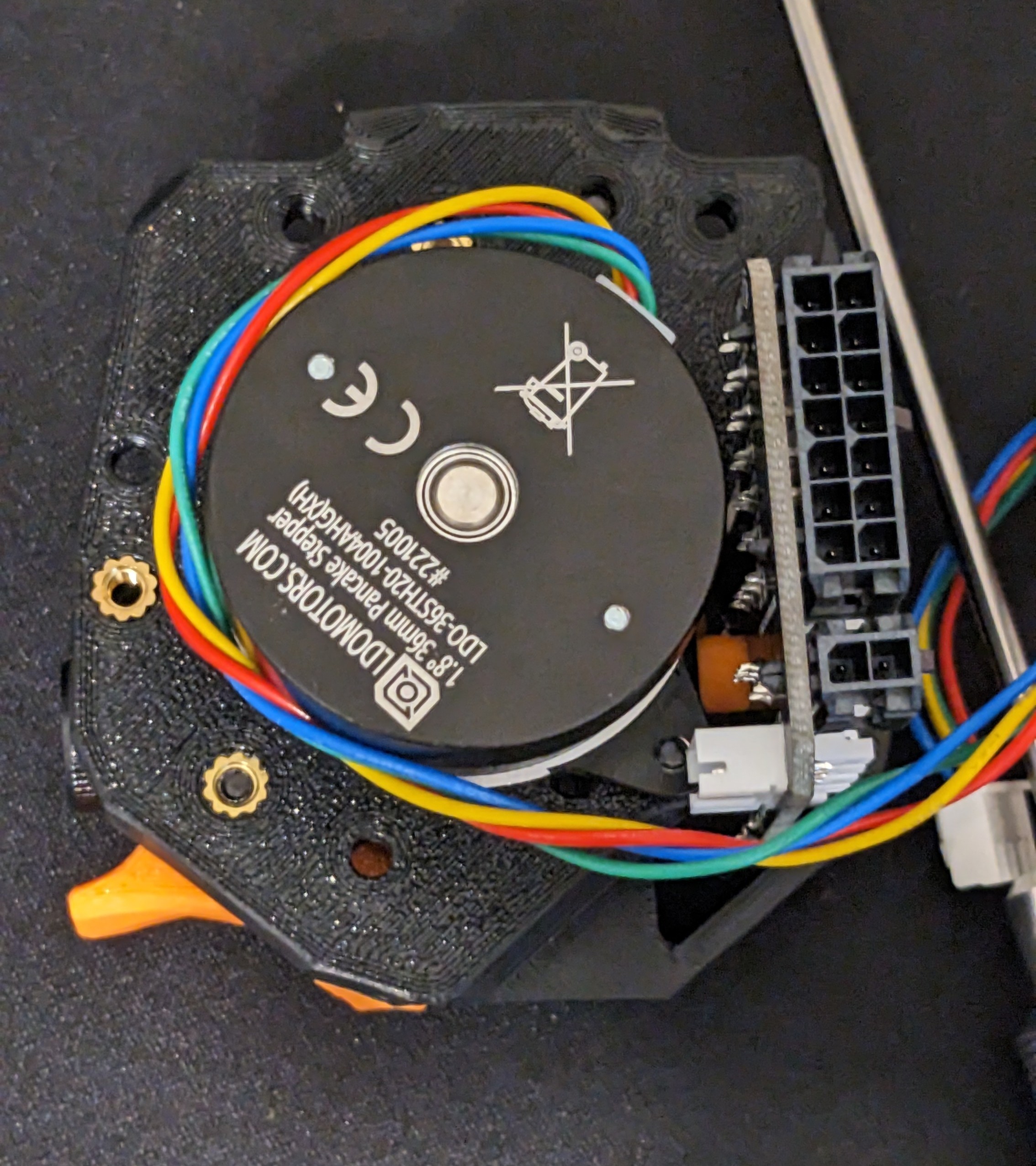

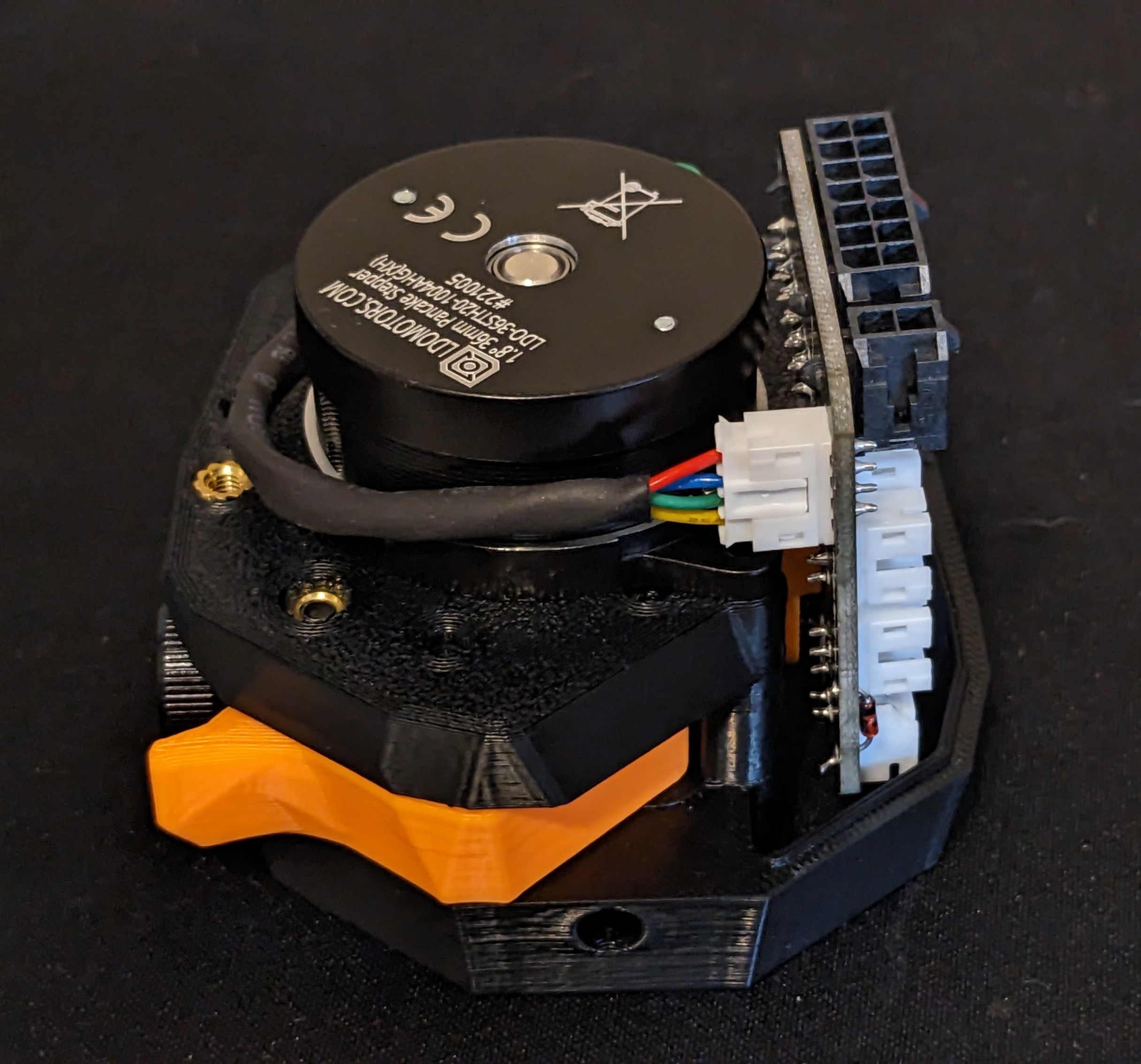

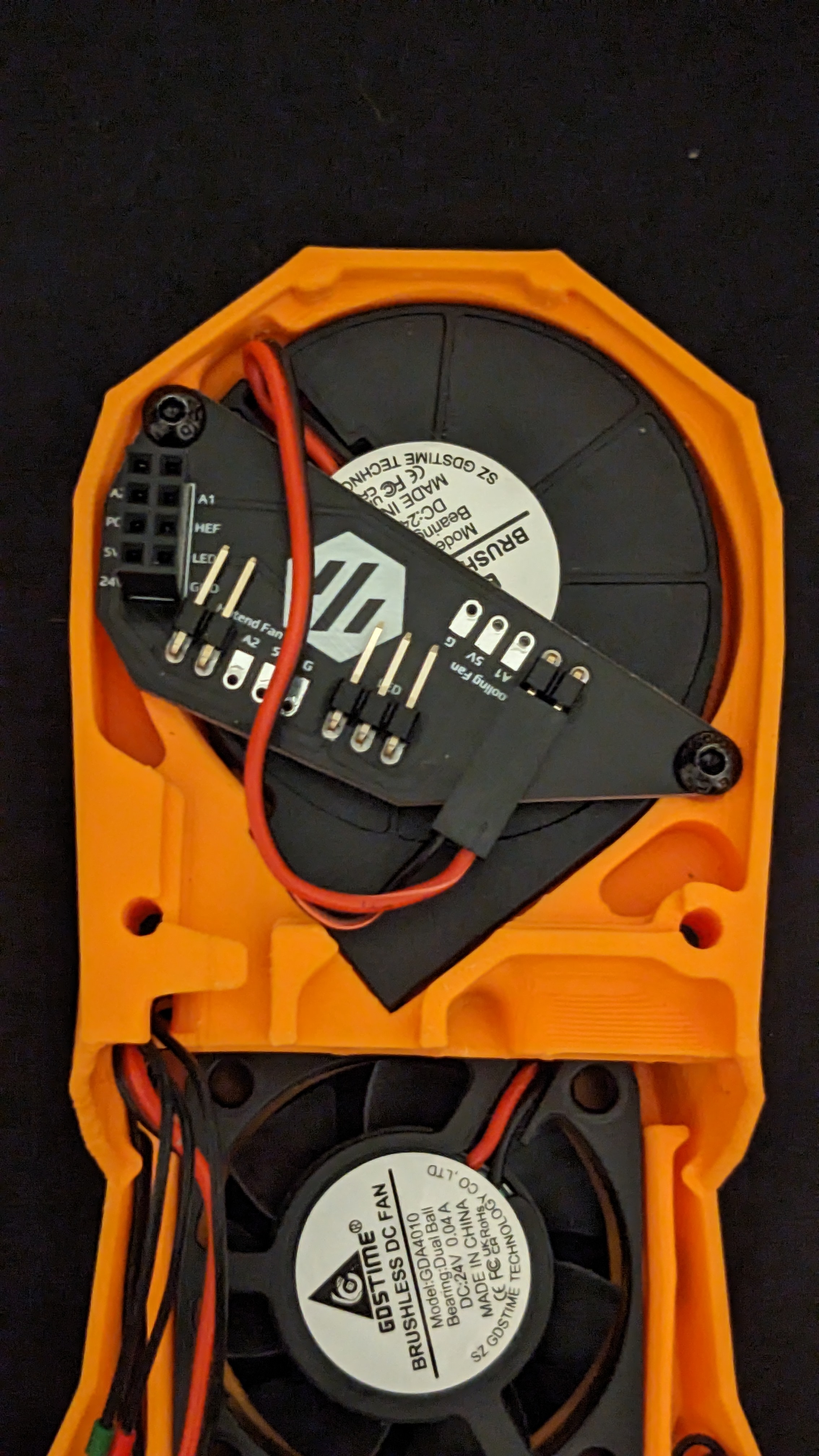

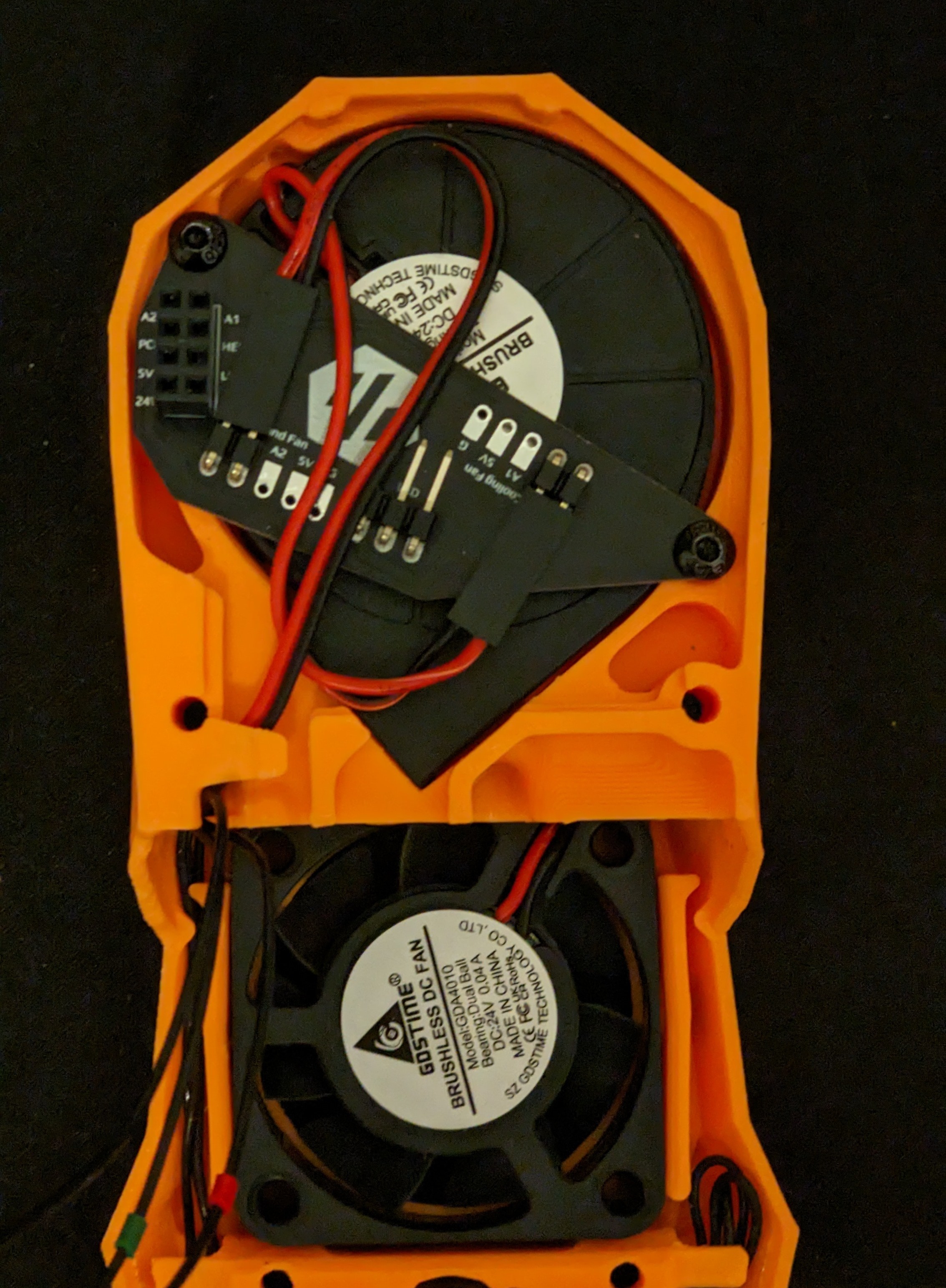

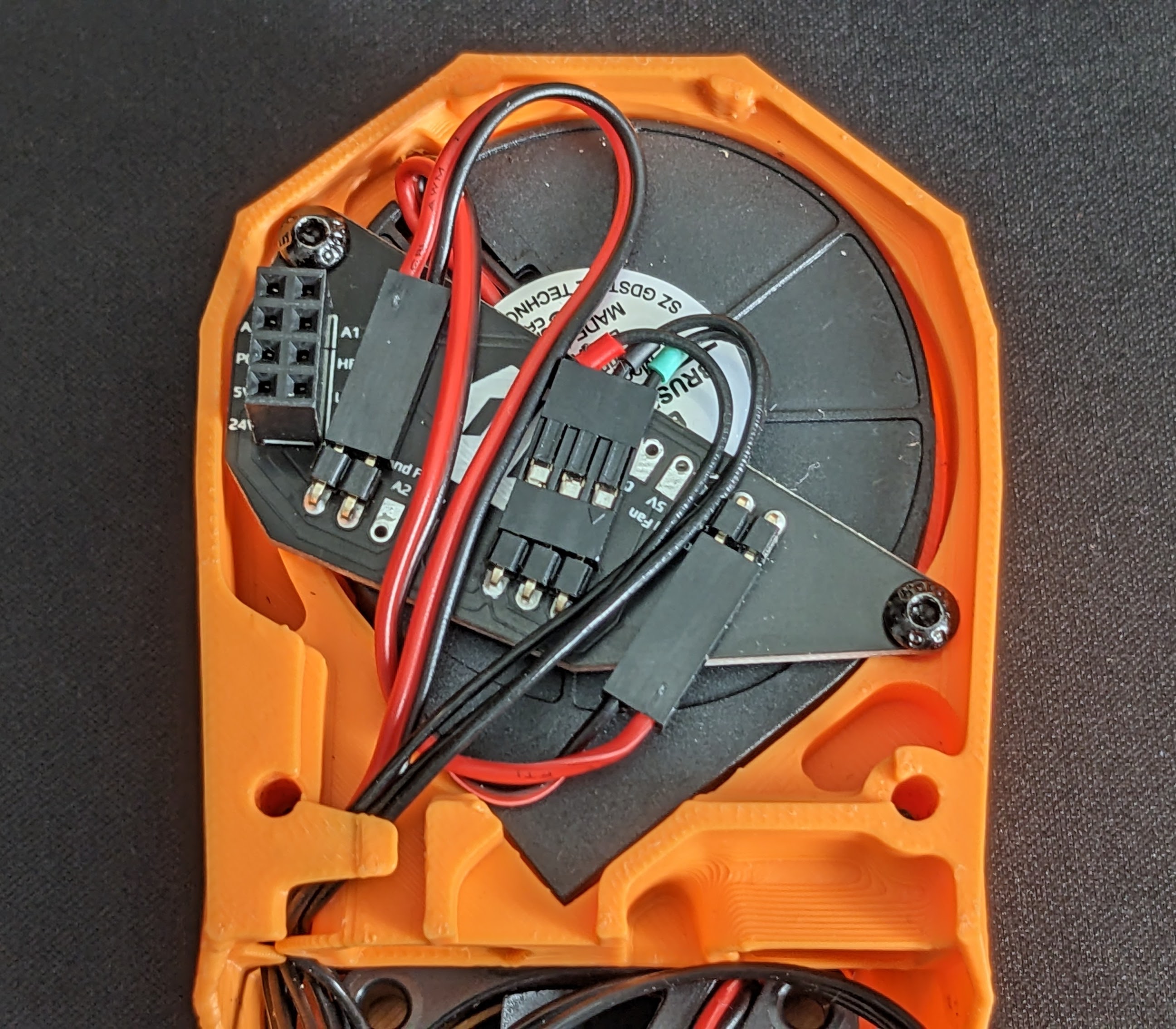

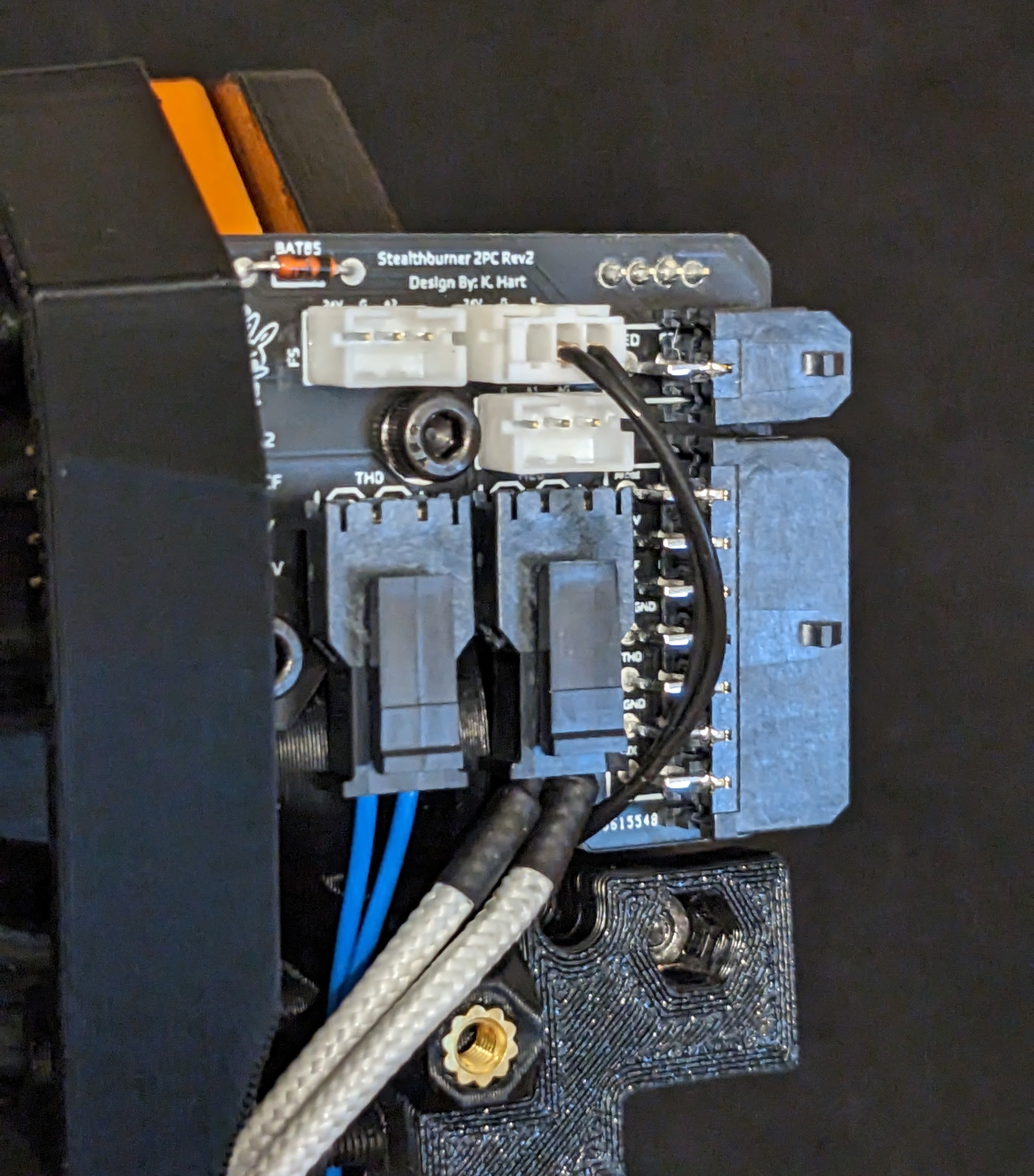

Place the PCB spacer on the back of the PCB, ensuring the raised section is facing the circuit board.

Then use the M3x8 screws to hold the PCB spacer in place, while you mount it to the CW2 body.

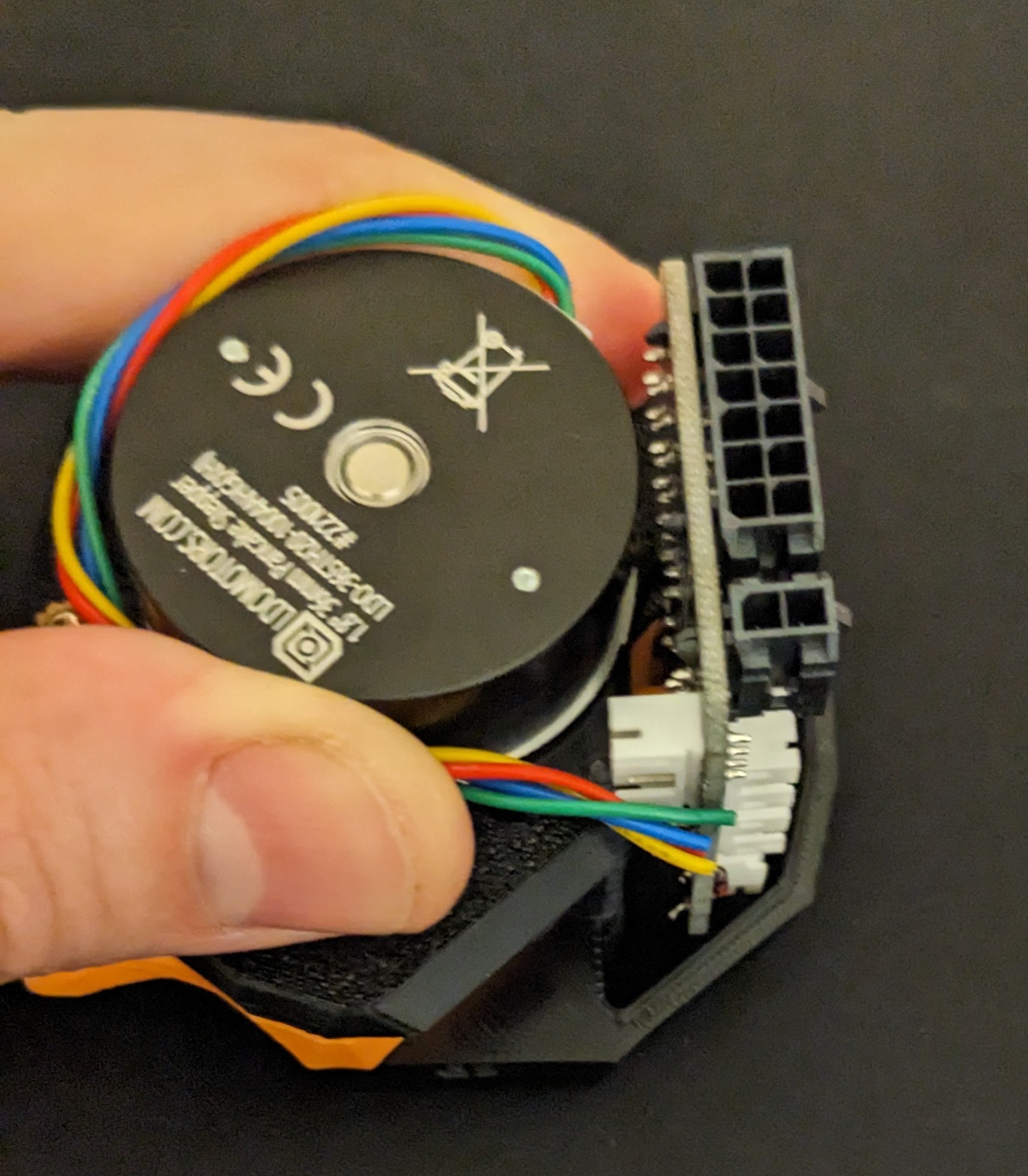

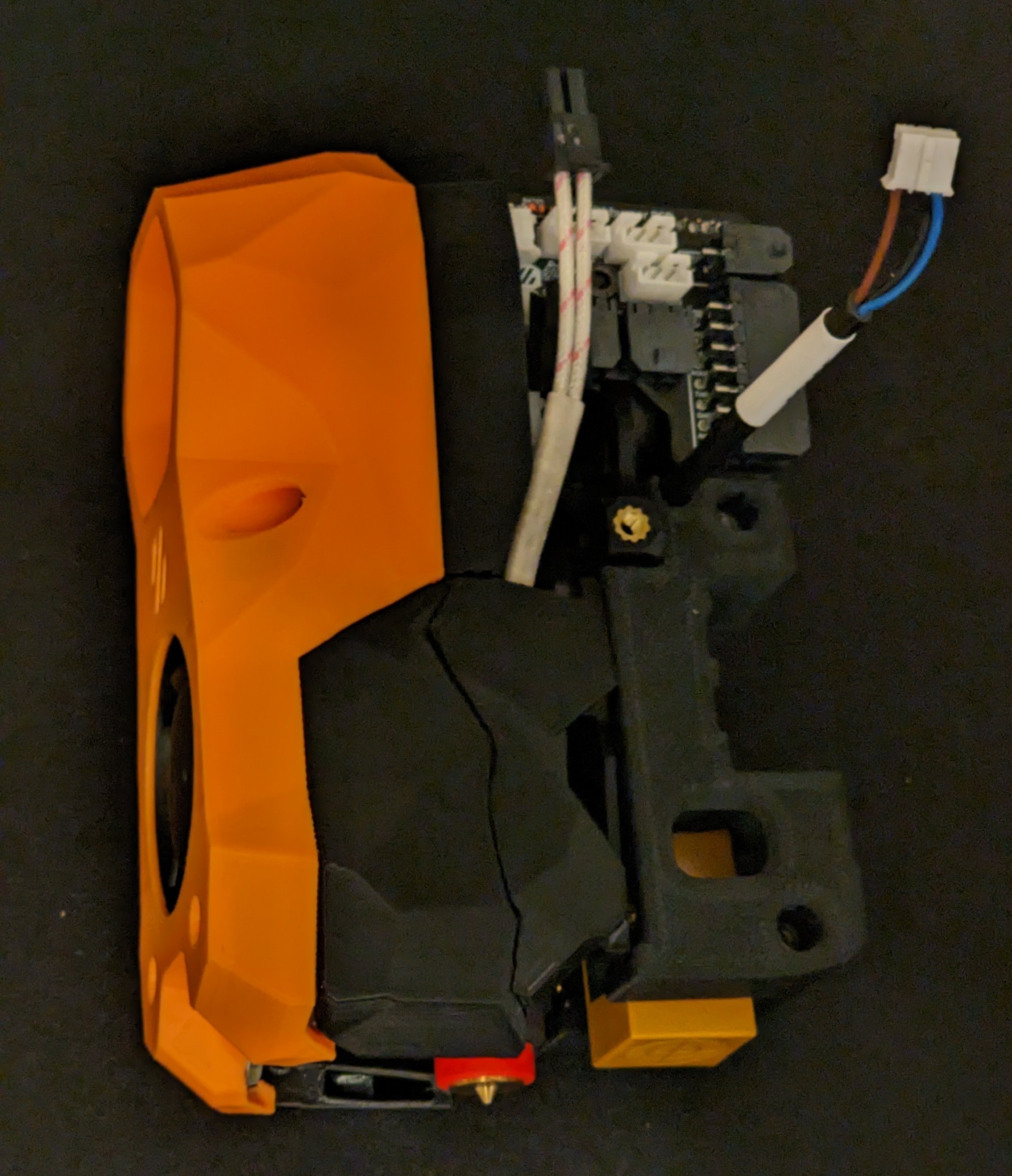

Next you will need to measure and cut the Extruder stepper motor wires.

Leave a little slack, and cut the wires.

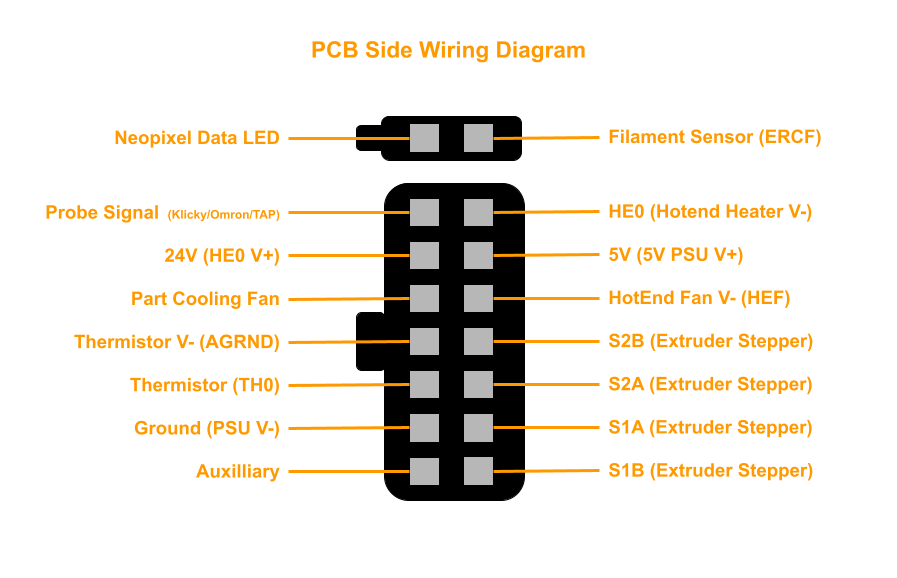

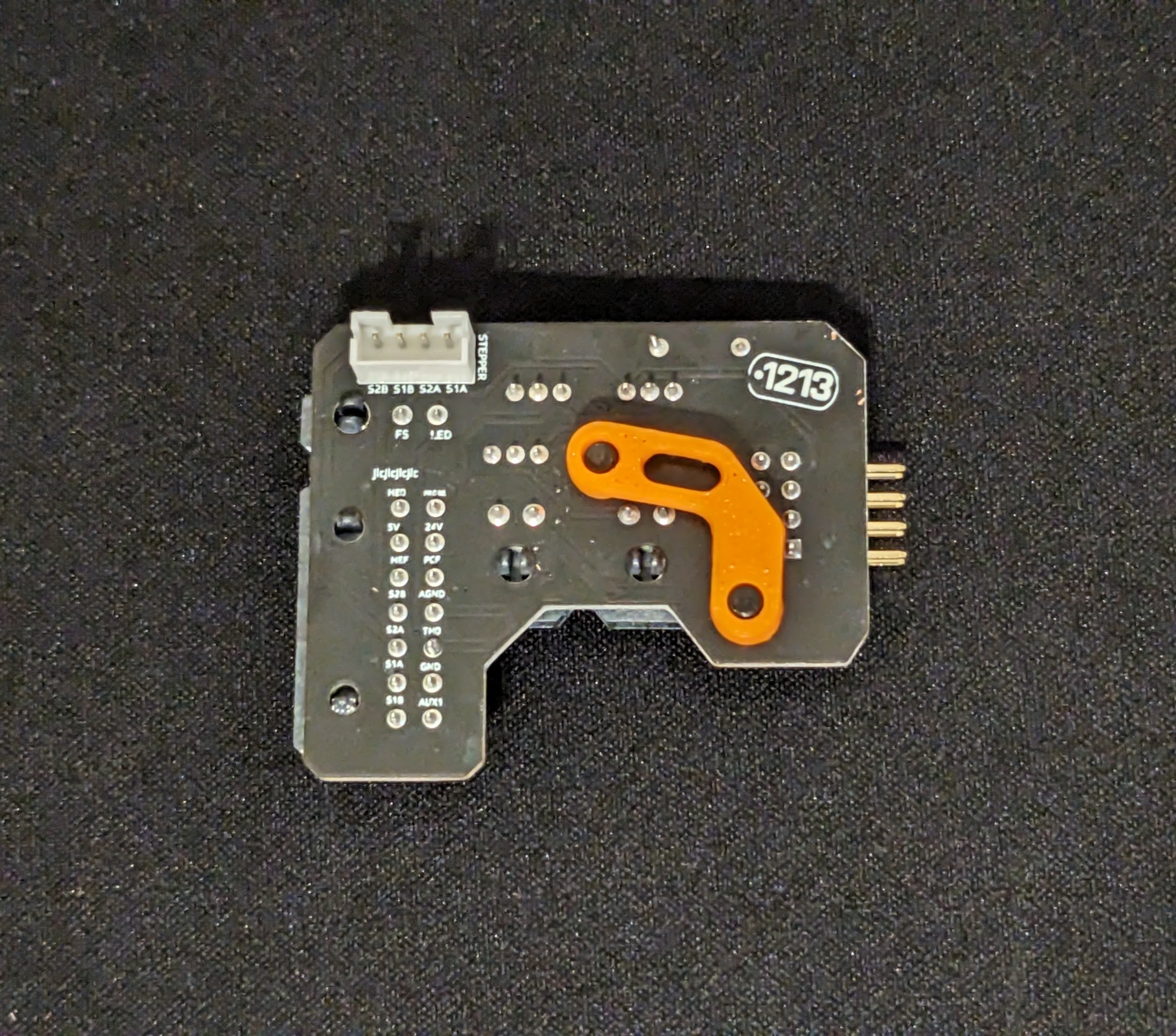

Strip the wires and install JST-PH terminals. JST-PH terminals are very small, on our Iwiss IWS-2820M, we recommend the 1.3 or 1.6 for these terminals. This guide from Digikey is very helpful. When installing the terminals in the connector, follow this image, as the pin-out is different when using the PCB.

Note: If you have the VRN edition of the stepper, the wires are a different color and order. They need to be Green, Red, Blue, Black (when looking from the top of the JST connector).

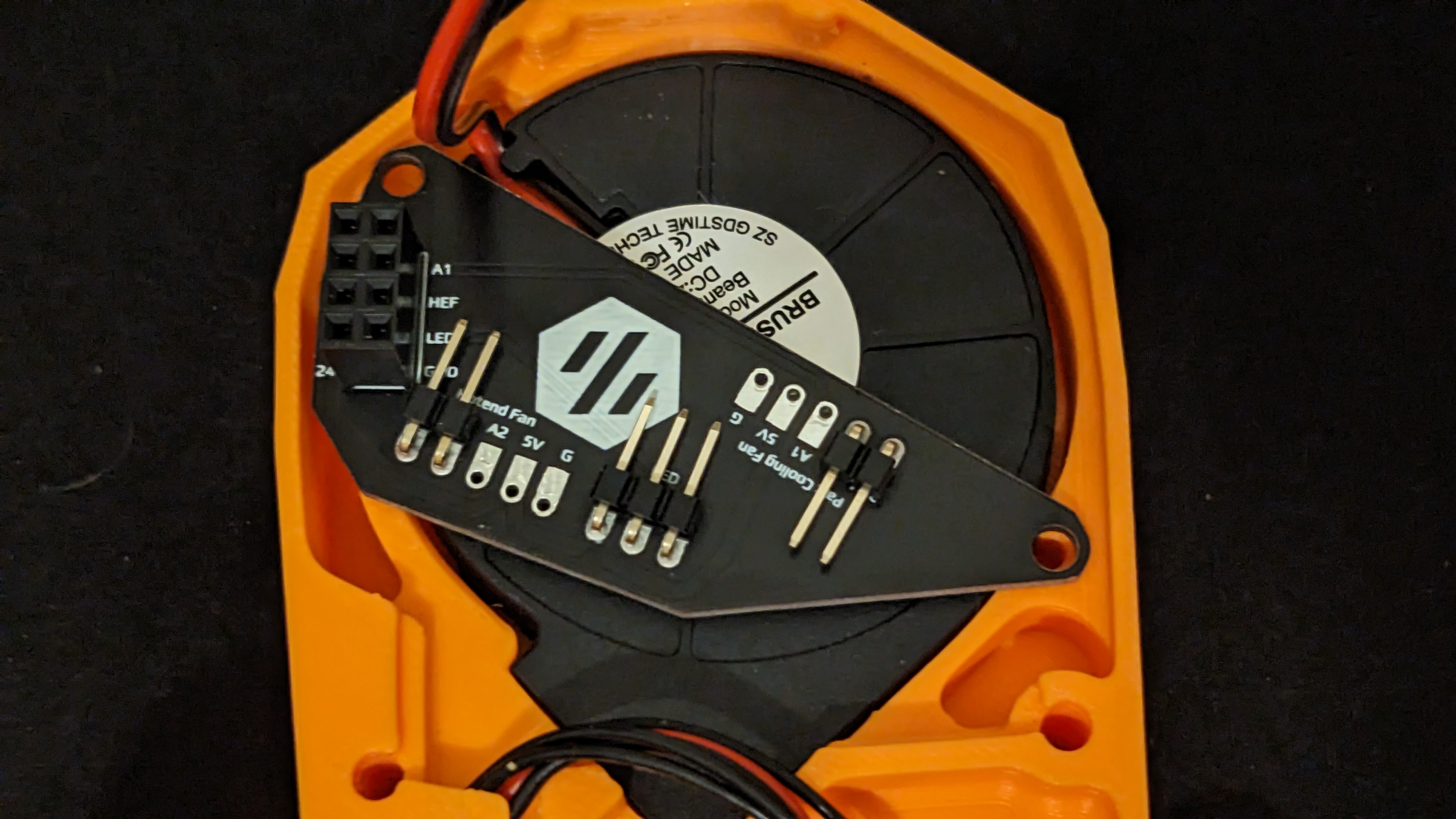

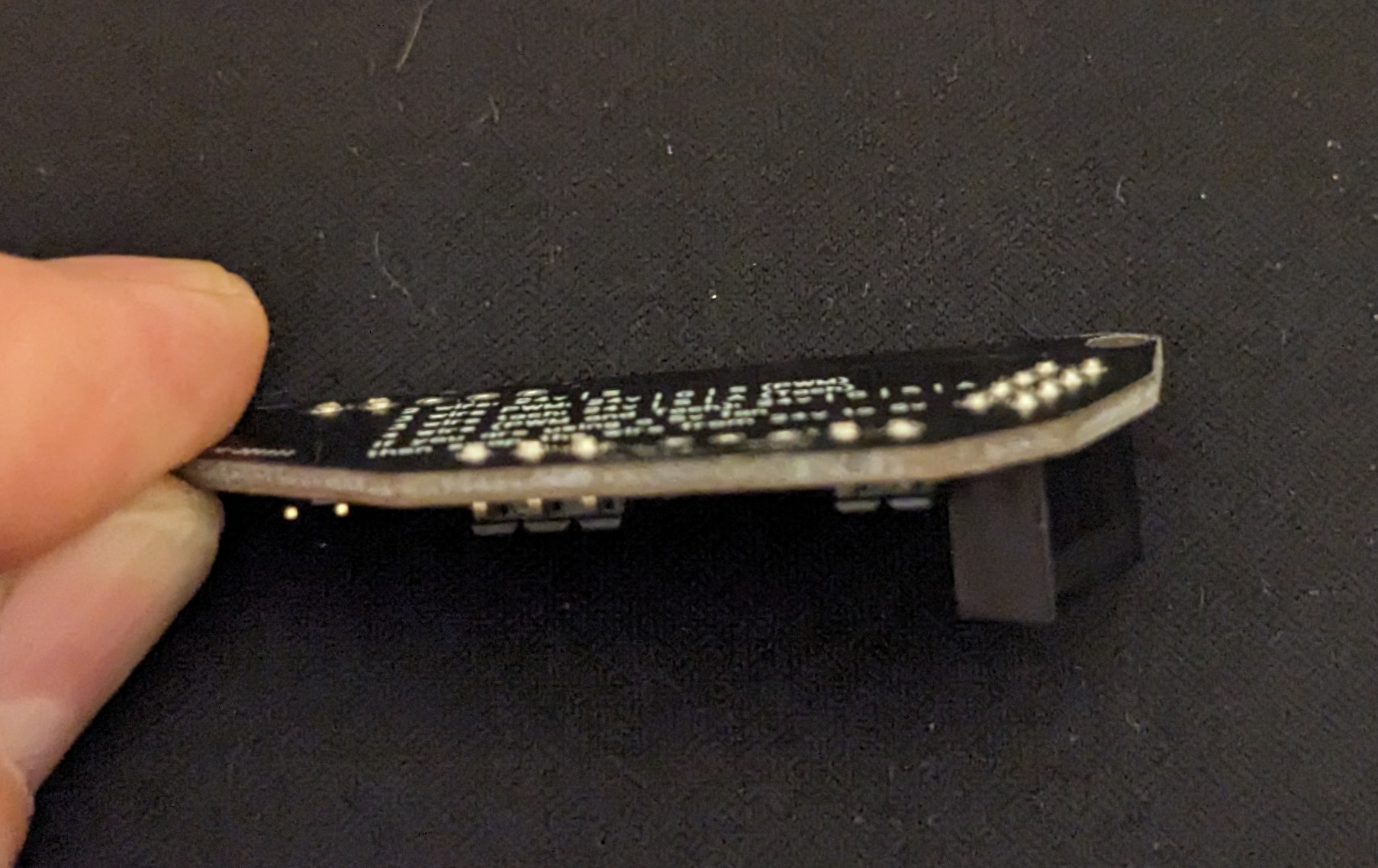

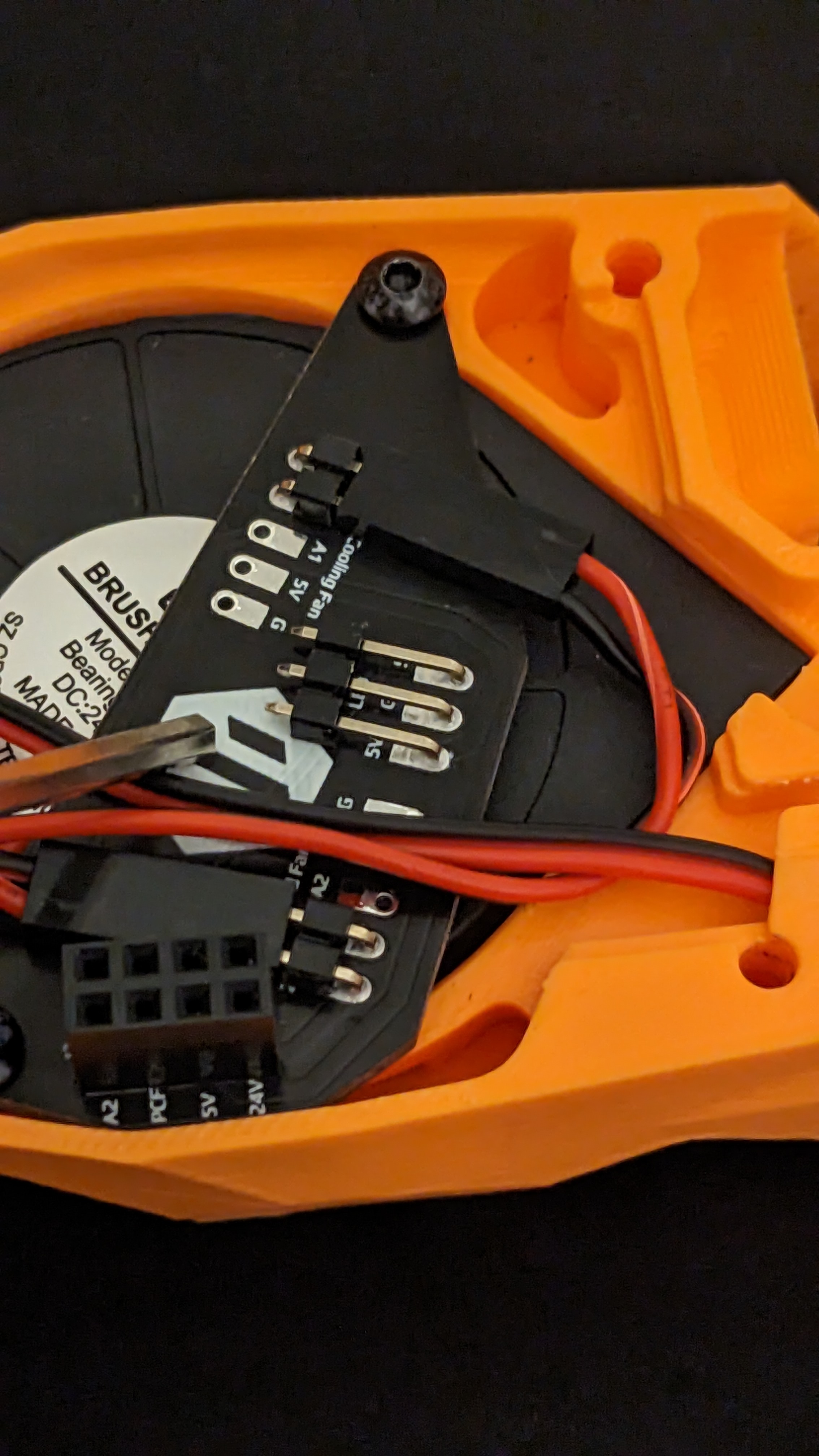

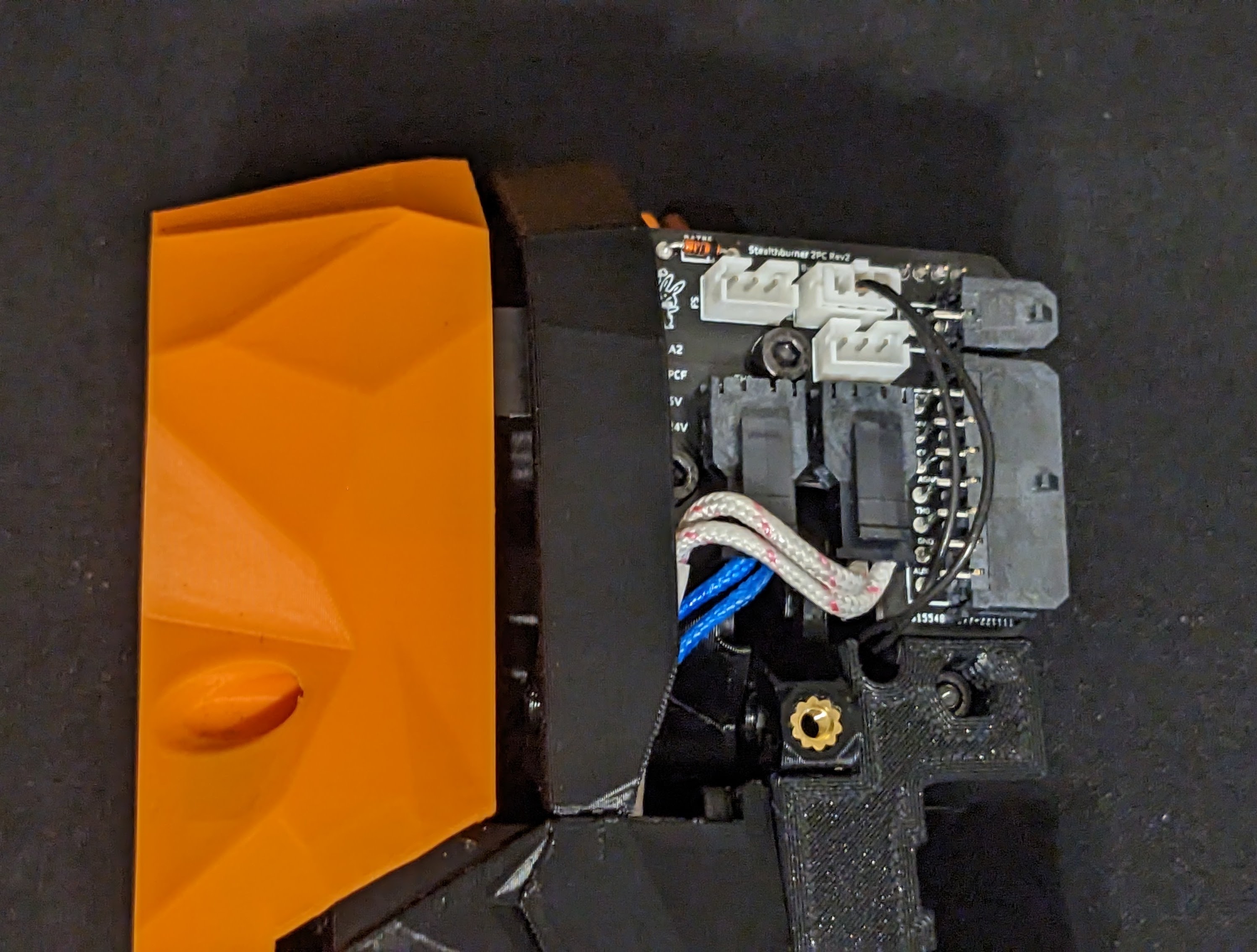

Moving to the front of the SB, you should test fit the front PCB to ensure it fits properly with your fans.

Sometimes you may need to trim the end of the soldered on headers on the back of the PCB with some flush wire cutters.

Once you have confirmed fitment, you can mount the PCB with two M3x6 BHCS.

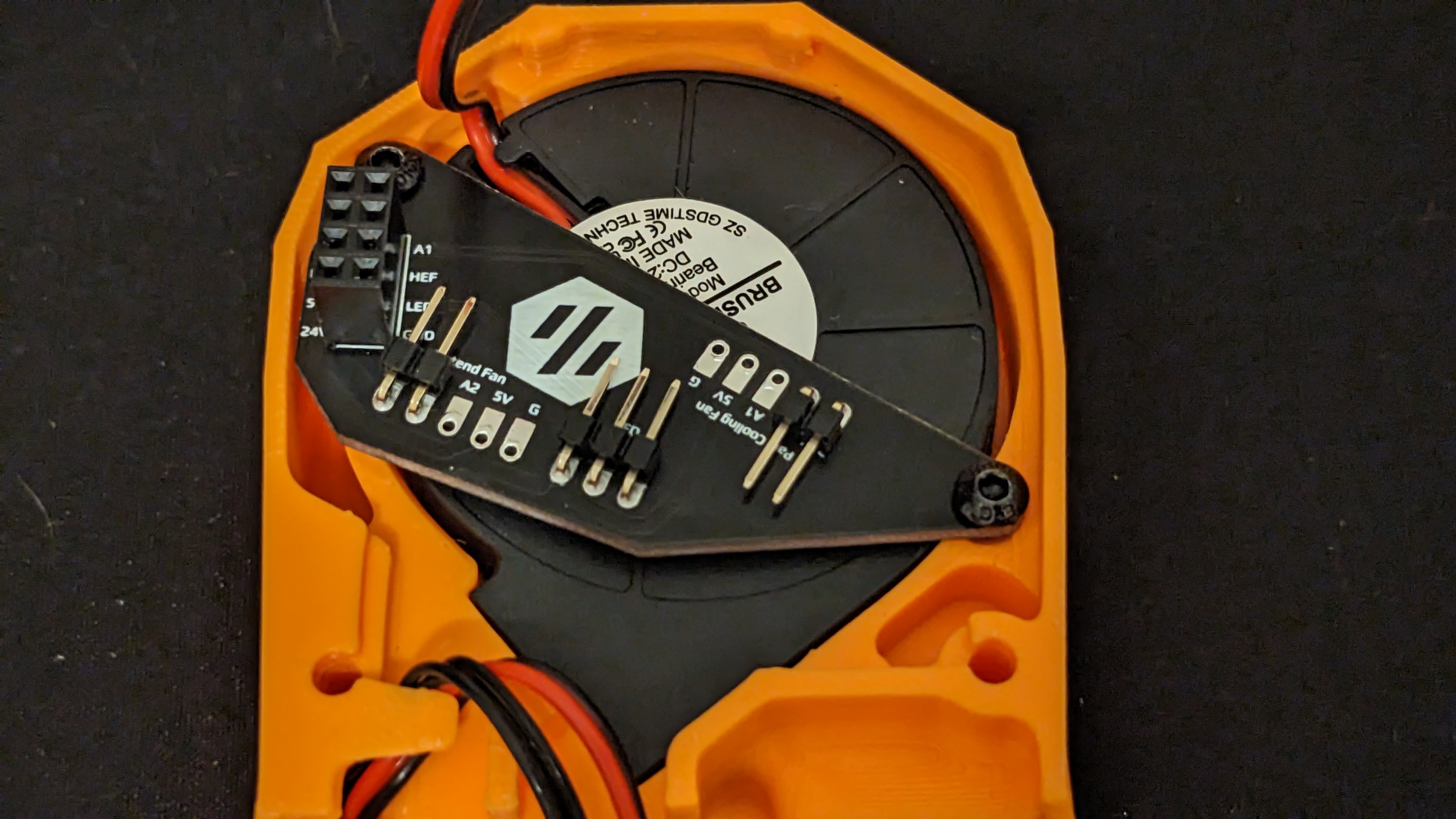

You will need to re-terminate your fans and possibly LED's. Our Linneo Toolhead RGBW LED Harness and Rainbow Barf harness are available pre-terminated with Dupont connectors.

Starting with the part cooling fan (the upper fan), leaving a little bit of slack (called a service loop), terminate the leads with a two pin Dupont connector. Double check your polarity each time you connect your fan, as the Dupont connector is not keyed (ie it can be installed either way).

Next move on to the Hot End Fan, again terminate it with a two pin Dupont connector.

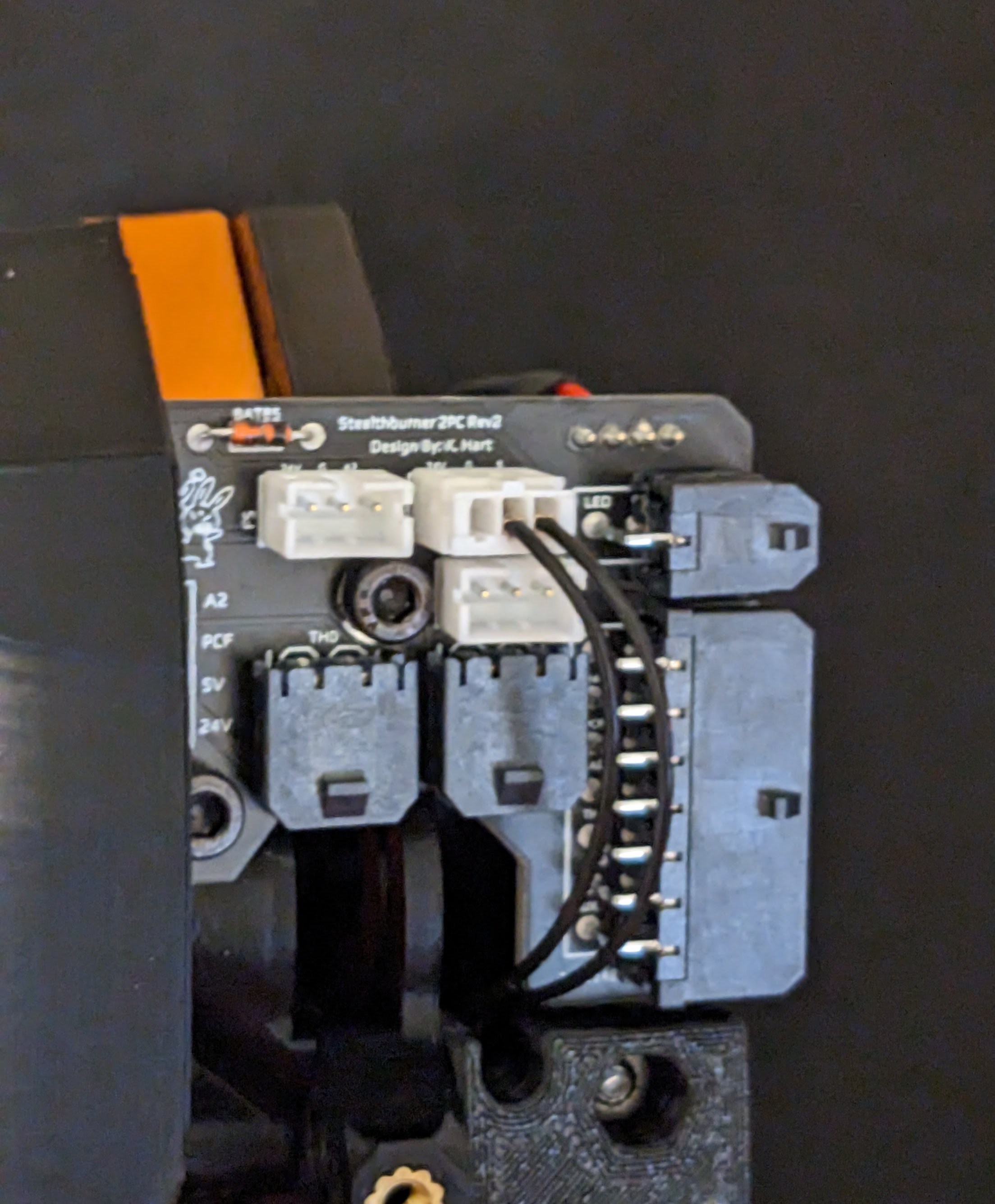

Lastly, if necessary, terminate your Neopixel LED wiring with a three pin Dupont connector. Before de-pinning or cutting the wires on your LED harness, ensure they are labeled to avoid mis-wiring. The PCB is labeled as to which connector is which, though the spacer on the header can obstruct the label.

Looking down at the PCB, with the PCF at the top, the wiring is 5V, Ground, Signal.

Before proceeding, double check your wiring.

Moving to the main PCB, if you are using an Omron style inductive probe, you may need to re-terminate your probe wires with JST-PH. Again, double check your wiring to make sure you wire your probe correctly. The PCB requires 24v, Ground, Signal in that order looking at the JST connector. Note: for the v3 PCB, you will need to use the 24v Probe port on the right.

For the Klicky probe, you will only need to use Signal and Ground. If you have a v3 PCB, you can use either port for Klicky.

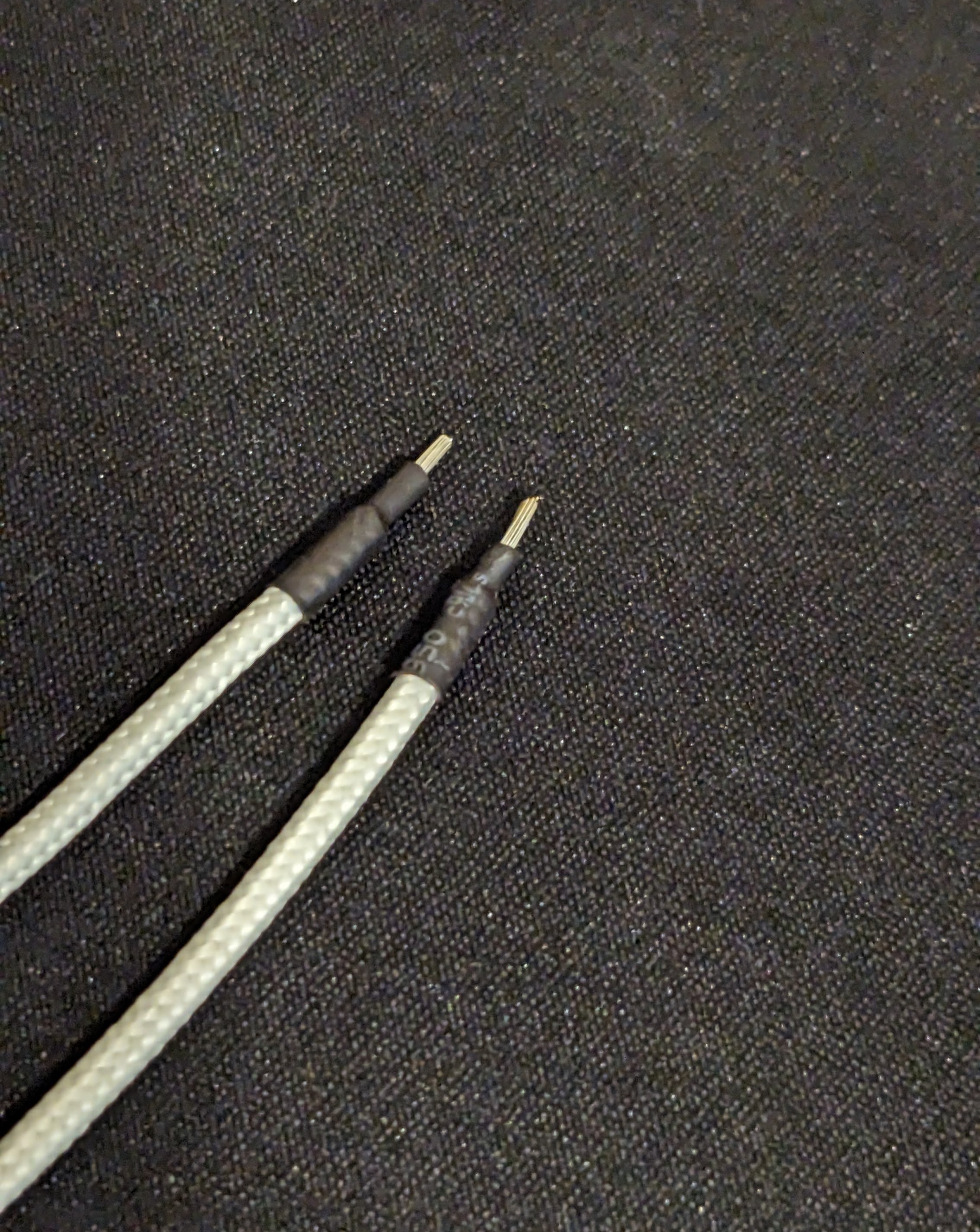

You will need to terminate your hotend heater and thermistor with 2-pin Molex Microfit 3.0 connectors (the Revo Voron come pre-terminated). Neither of these connectors are polarized (ie you don't need to ensure + / - order). When terminating heater wires, it can sometimes be easier to strip off extra insulation and use heatshrink tubing to cover the insulation and give you something more manageable to crimp on to.

When connecting the two PCB's for the first time, it can be helpful to loosen the screws holding the main PCB to the toolhead to give you some adjustability. Be Gentle to ensure you don't bend the pins on the front PCB.

This is the last of the toolhead specific wiring, for the Toolhead to MCU wiring, this guide is helpful. The pinout for the Molex connectors going to the MCU are below.