¶ Linneo Umbilical CAN XT30 Harness

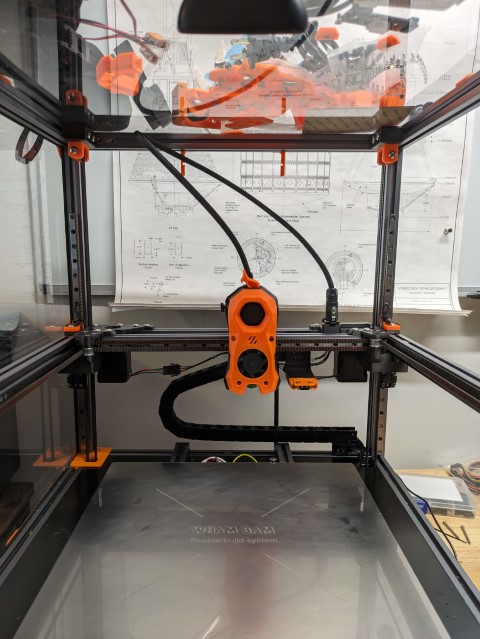

This guide will go over the installation of the Linneo Umbilical CAN XT30 Harness onto a Voron 2.4.

This guide can be used for a Molex harness as well but will be set to a different board on the toolhead.Linneo Umbilical CAN Molex Harness

We will be also installing the Mellow SB2040, We have a write up for this process here, you can follow this to install the Mellow SB2040 onto the printer.

¶ Setup

There are parts that need printed before you start this installation.

The parts that are needed are as follows with the links to the Github / Printables.

1: Y Endstop Relocation:

2: PG7 XT:30 Umbilical Mount:

Optional Parts

3: Z-Chain Relocation Parts:

This will relocate the z chain to be under the gantry, makes it cleaner.

4: Optional ADrive Umbilical Mounts

These are optional parts for users that are using other connector types than the 4 threaded hole option that comes with it.

¶ Installation Guide

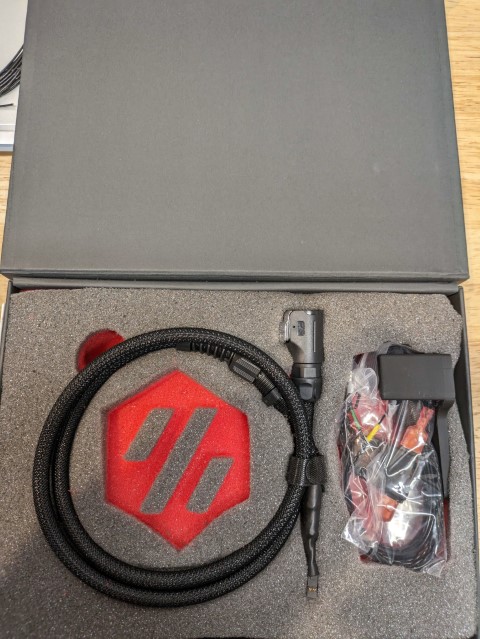

This is Linneo Umbilical XT30 Kit, this kit that we will be installing in this guide.

The Kit Contains the Followng.

1 - Pre Printed Umbilical Gland Mount.

1 - Hardware Kit

1 - Linneo Harness from under body to umbillical gland.

1 - Linneo Umbilical Cable XT30 End.

¶ Prepping Umbilical Mount

- First we will want to get the pre printed part and hardware kit.

- The Heat Press inserts need to be placed from the top side into the mount.

- Once this is cooled, we can detatch the power inlet fuse from the Linneo Harness and push the wires through the Top to the bottom so that we can mount the Umbilical Gland.

Note: Start all 4 screws and go in a star pattern around the gland to evenly put the gland onto the mount.

{.is-info}

¶ Y Endstop Relocation

We will be following the Github that was mentioned at the top to get this installed, we will add the information below to help going back and forth.

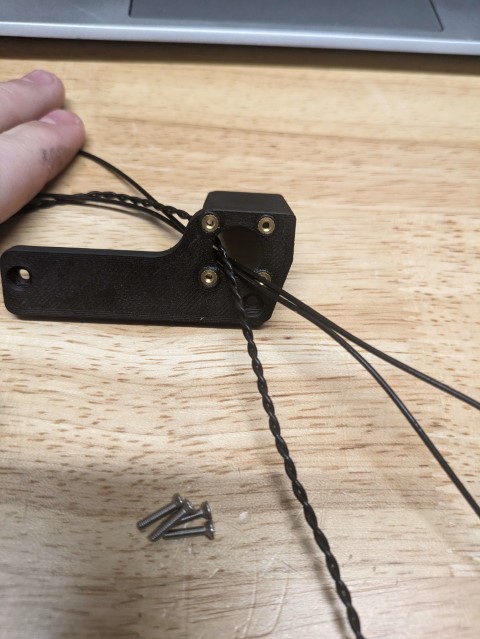

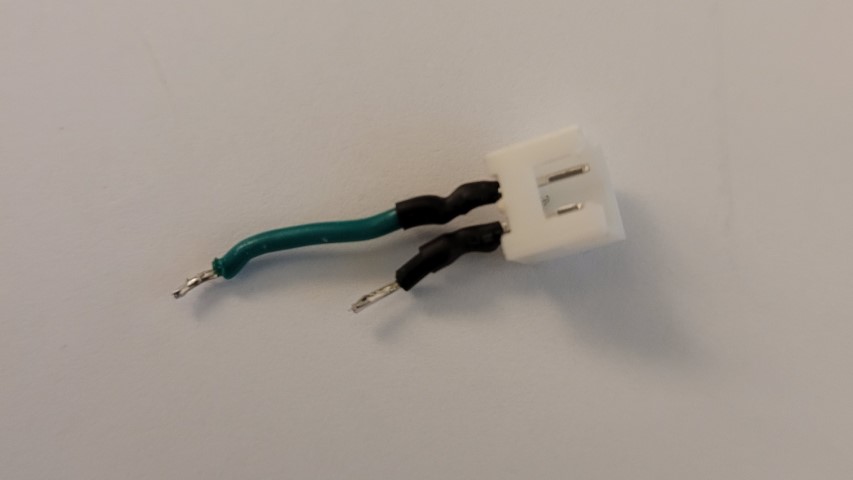

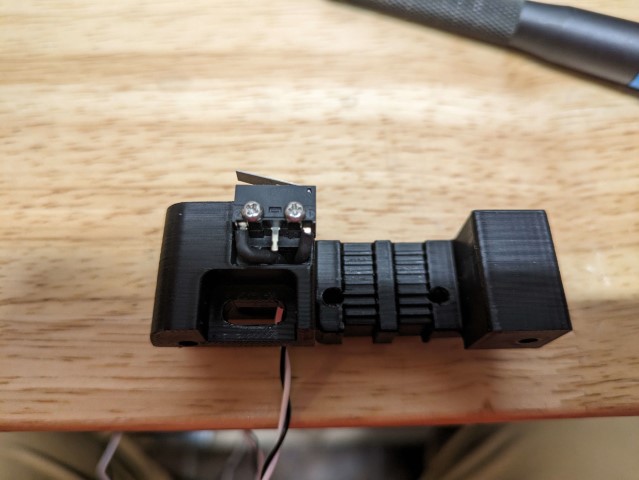

With the printed part we will want to get a JST female connector and slightly bend the pins so that they are bent like the picture below.

.png)

You will need to solder wires onto the pins so that they can make it through the channel that is modeled into the upper A Motor Mount.

One you have the wires attached you can add a dab of super glue to the back of the connector and place it through the channel to attach it to the mount.

After you have that you can mount the switch and solder the wires to the switch so that this can be all complete.

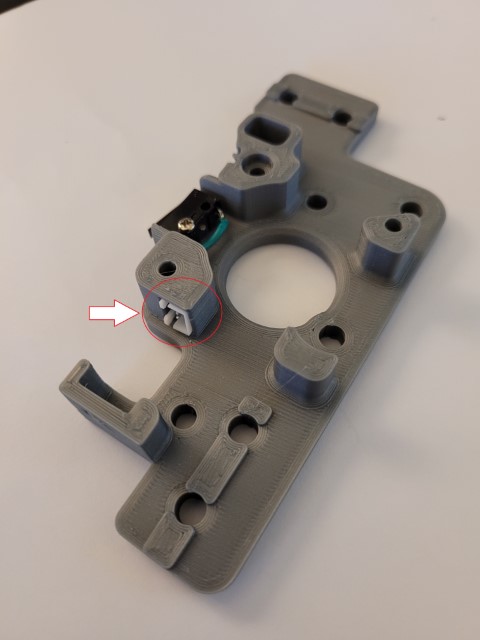

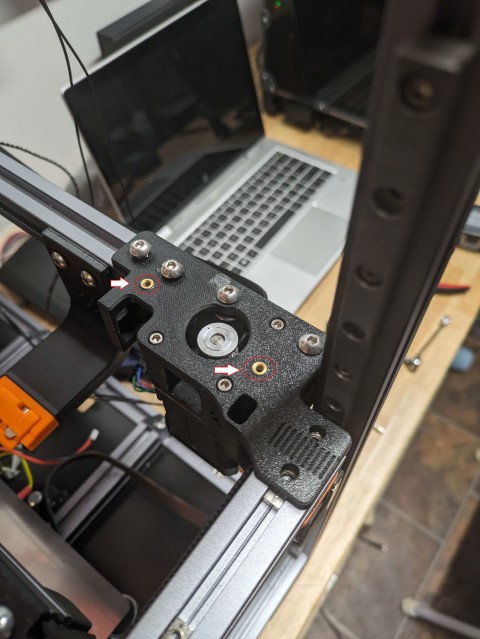

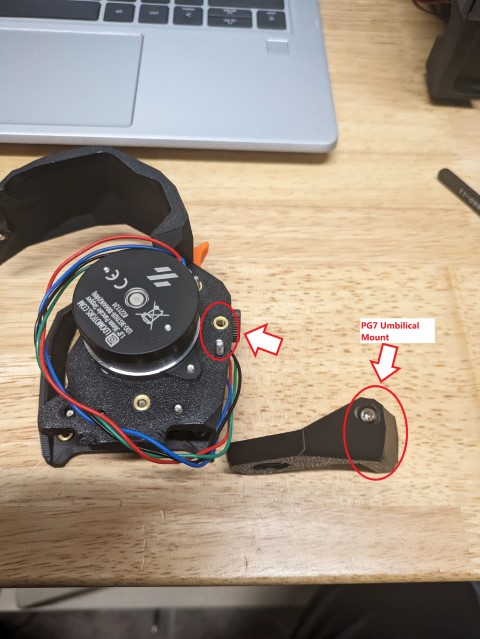

We will need to flip over the A motor mount and will need to add 2 heat press inserts into the following locations.

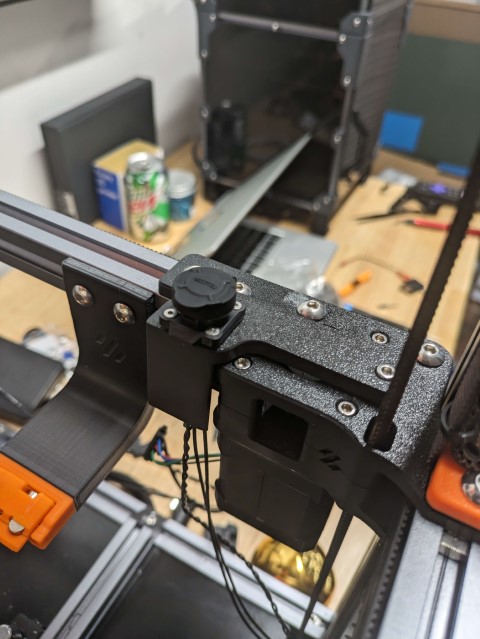

Once this is complete you can mount the Umbiical mount to the A Motor Mount.

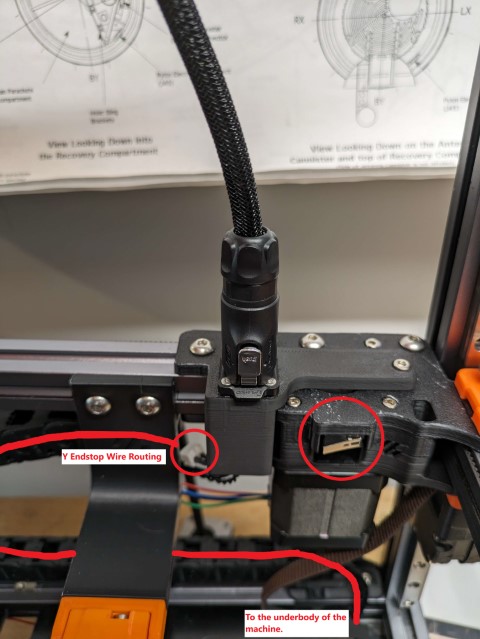

With the umbilical mounted you can route your wires into the underbody of the printer we will wire it up towards the end.

¶ X Endstop Relocation

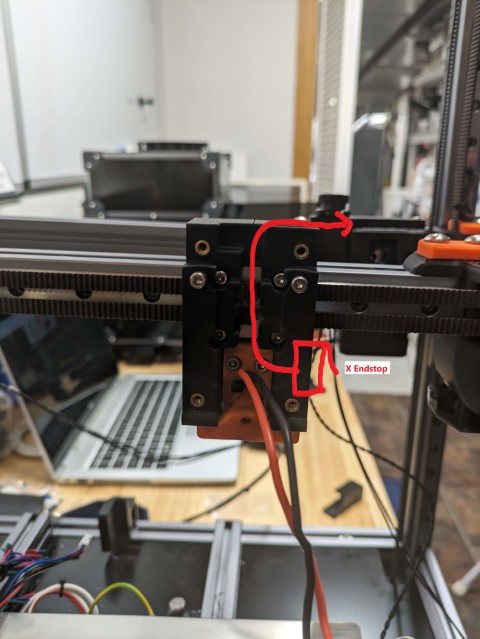

If you have a newer Voron 2.4 / Trident, the X Endstop location is placed by default onto the carraige parts that are done with the Print It Forward Program or the files from Voron's Github.

On the location that is see in the photo above you will need to route the wires through the hole by the mounting holes for the switch so that it can be routed up to the SB2040 when you remount the board.

Once you have the items wired through the hole and the switch mounted you can reattach the x carraige onto the linear rail carraige.

Make sure to route the wires throug the center channels and through the top channel as well, this is so that the tool head does not crush the wires.

¶ Mounting PG7 To Toolhead

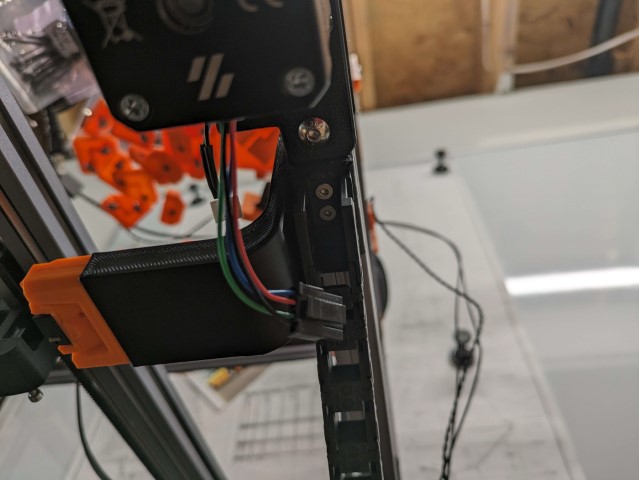

This section will go over the mounting of the PG7 Connection for the Toolhead.

This replaces the cable chain mount that is in the OEM kit.

There is a PG7 Umbilical Mount will need printed before installation.

The screw on the mount will thread into the inser that is on the right side of the motor, the screw on the tool head will screw into the PG7 Mount.

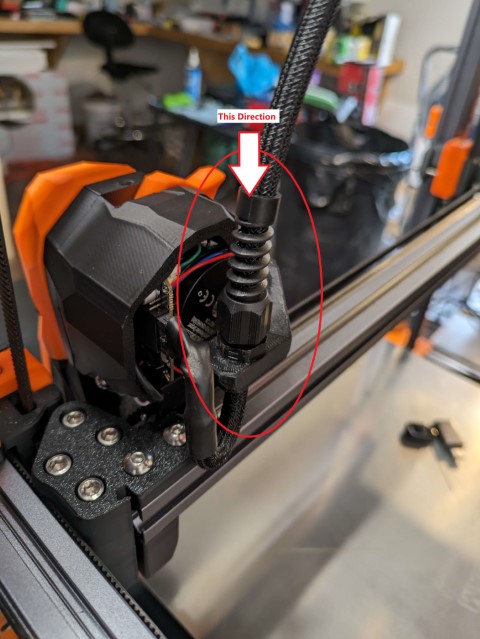

Once it is mounted it should look like the picture below.

You are safe to now mount the tool head to the carraige just like you took off to make this change.

Once you have the PG7 Mount set you can fish your Umbilical cable through the mount like so in this picture. You can adjust the cable length throug the gland if you are carefull, make sure that you have enough to make the bend to reach the toolhead board.

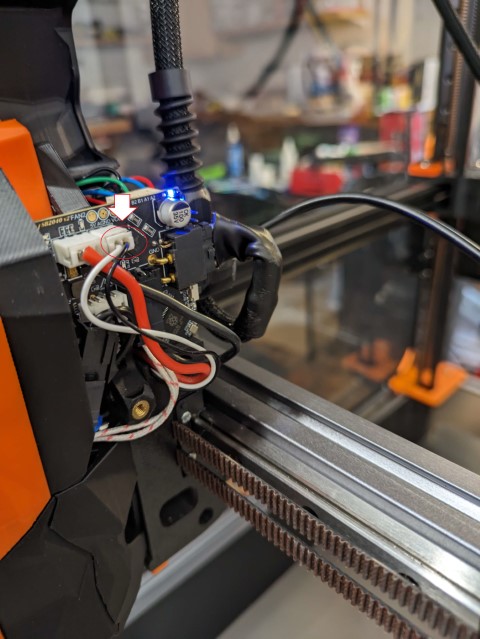

From this point you can make the bend to reach the toolhead board, Be aware, this may seem tight and most likely it will be but if you can make the bend like in the photo you can ensure that the umbilical will not hit the carraige or other axis's when homing or printing.

Dont forget to make the satisfying click onto the umbilical carraige connection as well.

¶ Misc Wiring Items

This section will go over the wiring for the X & Y endstops.

The X Endstop will get placed into the Mellow SB2040 board in the following location.

The Y Endstop Wiring will follow your cables for the Umbilical Harness where ever you are routing them, in my case it is in the zchain that has been relocated from our optional section.

The Canbus parts of the installation should be handled in the guide for installing the SB2040 Board to the printer. The Wiring of the endstops for the Y relocation should just go in the same position as before on the MCU.

You have Successfully Installed the Linneo Umbilical XT-30 Harnnes, Optional items will be listed below. If you have any questions please feel free to join our discord and us any questions in the chat or in a ticket.

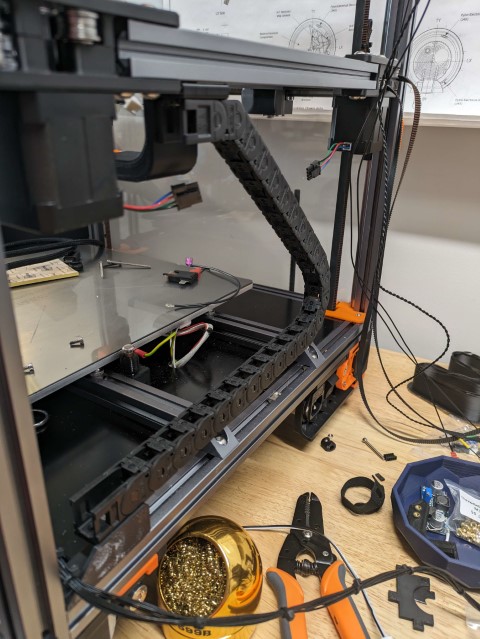

¶ Optional Z Relocation

In this section this is an optional item that you can do to make the installation of the umbilical look cleaner and not have to worry about the linneo harness flopping about in the chamber.

There are a few items that should be printed before the installation of the new Z Chain relocation kit.

Z-Chain Relocation Parts:

This will relocate the z chain to be under the gantry, makes it cleaner.

I personally was using klicky so i printed a version that incorporated the klicky dock, but they have a version that is standard to just the relocation.

-

Once you have removed all of the cable chains from the machine you can place either the x or y chain aside as we will be reusing this for the z in a few moments.

-

The reason we are switching out the Z chain to either the X or Y is because of the size of the chain, this is because the Z chain when leveling this will kink up and will cause the machine to not level properly, the carraige will try to push it out of the way.

-

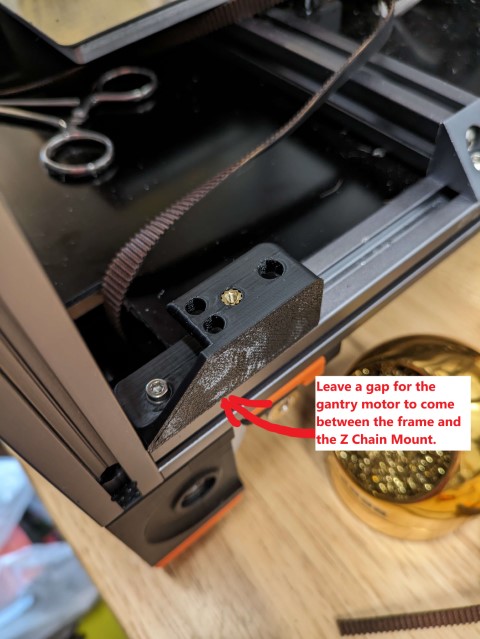

Once you have the parts printed you can moutn them with the M5 nuts and bolts ( if you were using Klicky, if not put a set in and use those for this mount).

As you can see this is mounted as far to the right towards the mount as it will allow me to place it. You can lock this down as we will not need this move in the future.

Once you have this mounted down you can move to the bottom mount,

There are two bolts you can use. You can reuse the old vertical mounting hardware for the Z Chain to add this on.

Once you have that mounted you can add the X Chain that we saved, you might have to flip one of the ends to make the orientation work properly but you can make it happen.

You can now add your back panel back on and it will never try to slip out of the printer, and the clearance will be golden for this.